China Hospitality Expo (che) es un evento anual para la industria hotelera china con raíces en el sur de China, que ofrece soluciones de ventanilla ún...

hotelex shanghai se llevará a cabo del 1 al 4 de abril de 2019 en el nuevo centro internacional de exposiciones de shanghai (2345 longyang road, pudon...

Exposición internacional de la industria del plástico y el caucho de Ucrania Tiempo de exposición: 4-7 de octubre de 2019. lugar: europa - ucrania ind...

Exhibición de tecnología de materias primas y equipos de producción de plásticos internacionales y kazajstán almaty tiempo de exposición: marzo de 202...

prev :

Introduction1 of 136H steel For Melamine Tableware Moldsiguiente :

718H Mould Steel-Introduction 2 precio de fábrica máquina de moldeo de vajillas de melamina con doble color

precio de fábrica máquina de moldeo de vajillas de melamina con doble color

nuestra máquina es adecuada para melamina, urea, baquelita, fibra y otra producción de material termoestable de productos de vajilla.

máquina de compresión automática de vajilla de melamina

máquina de compresión automática de vajilla de melamina

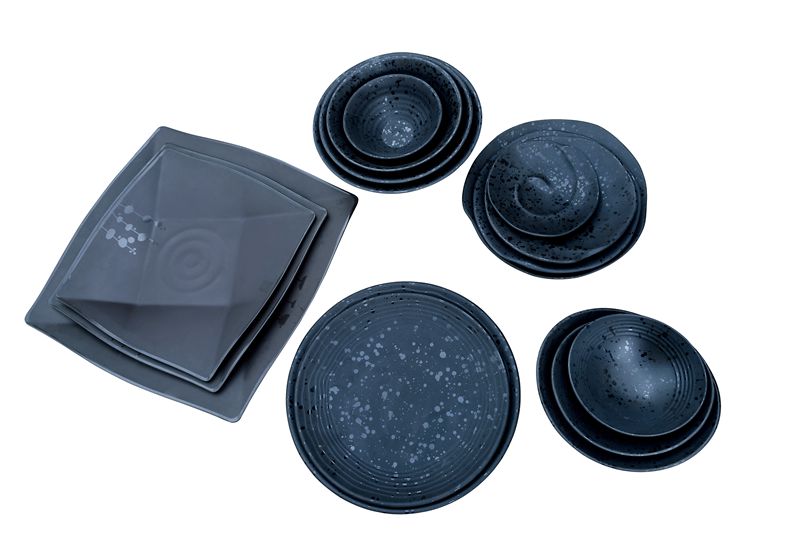

esta máquina es adecuada para todo tipo de compuestos de moldeo de melamina y compuestos de moldeo de urea, como la placa de melamina, el recipiente de melamina y la bandeja de melamina.

Máquina de moldeo de vajillas de melamina 2color

Máquina de moldeo de vajillas de melamina 2color

adecuado para la melamina, urea, baquelita, producción de fibra y otros materiales termoendurecibles de productos de vajilla. tal como tazón, taza, plato, palillos chinos, cuchara, plato, caja de torta, imitación de almidón porcelana vajilla fibra vegetal imitación porcelana vajilla placa fibra vajilla de porcelana de imitación y así sucesivamente.7

máquina de compresión de la cubierta de asiento de inodoro uf / urea control plc

máquina de compresión de la cubierta de asiento de inodoro uf / urea control plc

varias operaciones de moldeo de baquelita, uso para la cubierta del asiento del inodoro ufc y mdf.

buen precio 5kw precalentador máquina para vajilla de melamina

buen precio 5kw precalentador máquina para vajilla de melamina

máquina del precalentador para la vajilla de la melamina / la máquina de moldeo de la vajilla de la melamina / el compuesto de la melamina que moldea

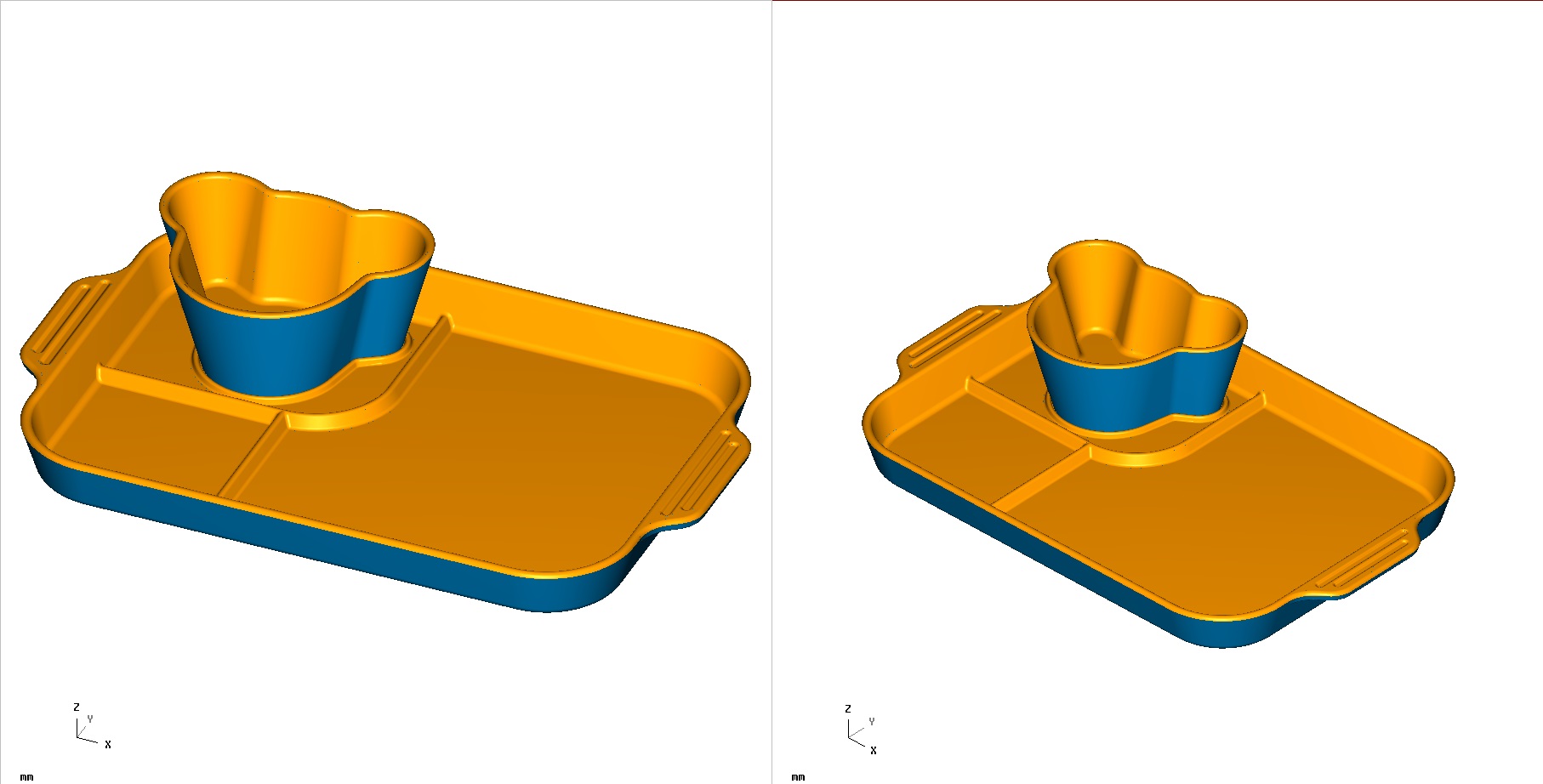

Planta de moldes de vajilla de melamina de China con 4cavity

Planta de moldes de vajilla de melamina de China con 4cavity

Planta de moldes de vajilla de melamina de China con 4cavity

taller de espectáculo

taller de espectáculo

productos muestran

productos muestran

video show

video show

nuestros certificados

nuestros certificados

el equipo profesional al servicio !